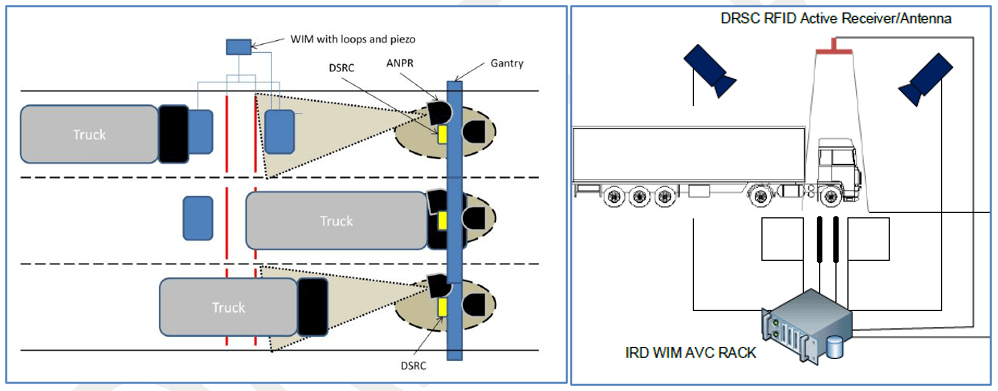

Weigh-in-motion or weighing-in-motion devices (WIM) are designed to capture and record the axle weights and gross vehicle weights as vehicles drive over a measurement site. Unlike static scales, WIM systems are capable of measuring vehicles traveling at a reduced or normal traffic speed and do not require the vehicle to come to a stop. This makes the weighing process more efficient, and, in the case of commercial vehicles, allows for trucks under the weight limit to bypass static scales or inspection.

WIM systems can employ various types of sensors for measurement. The most important quantity to measure is the vertical force (z component) without any influence of forces in other directions or speed of the vehicle that passes by. Force sensors with quartz crystals are the most rigid and measure only in one direction along the vertical axis. When a force is applied to the top surface of the sensor, quartz crystals produce an electric charge proportional to the applied force. The signal is a very high impedance electric charge, which is not susceptible to electrical interference.

Inductive loops define the vehicle entry and exit from the WIM station. These signals are used as triggering inputs to start and stop the measurement to initiate totaling gross vehicle weight and length of each vehicle. For toll gate or low speed applications, inductive loops may be replaced by other types of vehicle sensors such as light curtains, axle sensors or piezo cables.

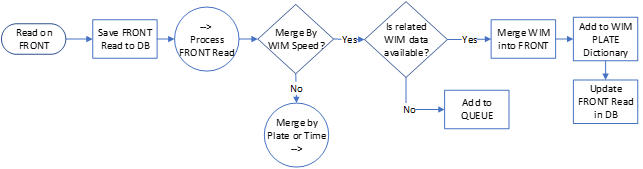

- A FRONT Read is a Read, on the camera, which is a target of the merge relation (is listed in the Merges list of another camera)

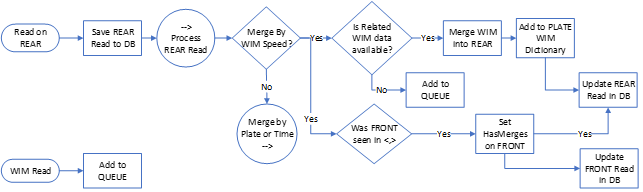

- A REAR Read is a Read on the camera, which is a source of the merge relation (has some cameras listed in the Merges list)

- A Control Point (CP) Read is a Read on a camera, which is the target of the Slave relationship (it is listed in the Slaves list of another camera) and has the "Allow enhanced data" selected. CP Reads are treated separately, no matter if they are Front or Rear License Plates. Each license plate is used to search for related images.

- A QUEUE is a list in memory of recent Reads of any kinds.

- PLATE WIM Dictionary is a dictionary of Plate to WIM relations in memory.

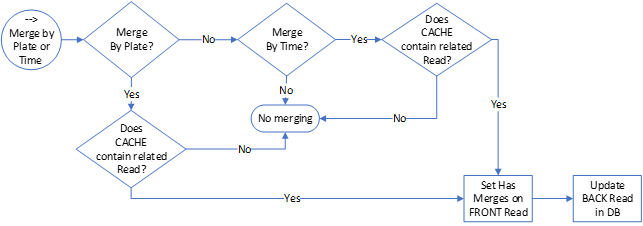

(*) Merge on Plate or Time is the old way of merging, where WIM data is not involved.